Iileyile eziqhelekileyo ziileyile ezithe tyaba ezinokuthi ziqhubekekise iintlobo ezahlukeneyo zezixhobo zokusebenza ezifana neeshafti, iidiski, iiringi, njl njl.

umsebenzi wesakhiwo

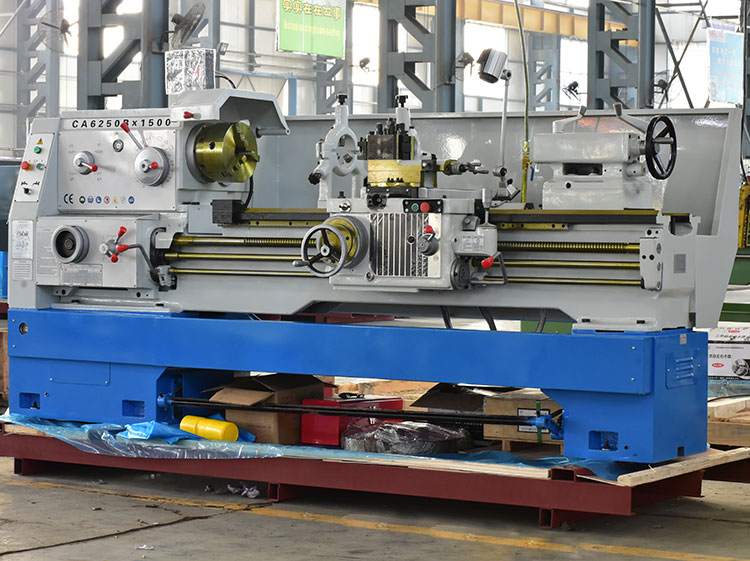

Amacandelo aphambili e-lathe eqhelekileyo zezi: isitokhwe sentloko, ibhokisi yesondlo, ibhokisi yesilayidi, indawo yokuphumla kwesixhobo, umsila, isikrufu esigudileyo, isikrufu sokukhokela kunye nebhedi.

I-Headstock: Ikwabizwa ngokuba yi-headstock, umsebenzi wayo ophambili kukugqithisa intshukumo ejikelezayo ukusuka kwimoto ephambili ngothotho lweendlela zokutshintsha isantya ukuze i-shaft ephambili ikwazi ukufumana izantya ezahlukeneyo ezifunekayo zokuya phambili kunye nokubuyela umva, kwaye kwangaxeshanye isitokhwe sentloko sahlula inxalenye yamandla Dlula isindululo kwibhokisi yesondlo.I-Headstock Medium spindle yinxalenye ephambili ye-lathe.Ukuguda kwe-spindle esebenzayo kwi-bearing kuchaphazela ngokuthe ngqo umgangatho wokucubungula we-workpiece.Emva kokuba ukuchaneka kokujikeleza kwe-spindle kuncitshisiwe, ixabiso lokusetyenziswa kwesixhobo somatshini liya kuncitshiswa.

Ibhokisi yesondlo: Ikwabizwa ngokuba yibhokisi yesixhobo, ibhokisi yesondlo ixhotyiswe ngendlela yokutshintsha isantya sokutya intshukumo.Lungisa indlela yokutshintsha isantya ukufumana isixa sesondlo esifunekayo okanye inowuthi, kwaye uthumele intshukumo kwimela ngesikrufu esigudileyo okanye isikrufu sokukhokela.irack yokusika.

I-Lead screw kunye ne-screw egudileyo: isetyenziselwa ukudibanisa ibhokisi yokutya kunye nebhokisi yesilayidi, kunye nokuhambisa intshukumo kunye namandla ebhokisi yokutya kwibhokisi yesilayidi, ukuze isilayidi.

phila phezulu

Ikhreyithi ifumana intshukumo yomda welongitudinal.Isikrufu sokukhokela sisetyenziselwa ngokukodwa ukujika imisonto eyahlukeneyo.Xa ujika ezinye iindawo ze-workpiece, i-screw smooth kuphela isetyenzisiweyo, kwaye i-screw lead ayisetyenziswanga.

Ibhokisi yeSilayidi: Yibhokisi yolawulo yentshukumo yokutyisa kweleyile.Ixhotyiswe ngomatshini oguqula ukushukuma okujikelezayo kwebha yokukhanya kunye nesikrufu sokukhokela sibe sisindululo somgca sokuphumla kwesixhobo.Intshukumo yokutya okude kunye nentshukumo yokutya enqamlezileyo yokuphumla kwesixhobo kufezekiswa ngokuhanjiswa kwebar yokukhanya.Kwaye intshukumo ekhawulezayo, ngesikrufu ukuqhuba isibambi sesixhobo ukwenza intshukumo yomgca wobude, ukuze ujike umsonto.

Isibambi sesixhobo: Isibambi sesixhobo siqulunqwe ngamaleya aliqela wabaxhobi besixhobo.Umsebenzi wayo kukuxinanisa isixhobo kwaye wenze isixhobo sihambe ngobude, ecaleni okanye ngokuthobileyo.

I-Tailstock: Faka iziko elingasemva kwinkxaso yokubeka indawo, kwaye unokufaka izixhobo zokulungisa umngxuma ezifana ne-drills kunye ne-reamers yokucubungula umngxuma.

Ibhedi: Iindawo eziphambili ze-lathe zifakwe ebhedini, ukuze zigcine indawo echanekileyo yesalamane ngexesha lomsebenzi.

isihlomelo

1. I-chuck yemihlathi emithathu (yemisebenzi ye-cylindrical), i-chuck yemihlathi emine (yemisebenzi engaqhelekanga)

2. Iziko eliphilayo (lokulungisa izixhobo zokusebenza)

3. Isakhelo sembindi (i-workpiece ezinzileyo)

4. Ngesiphatho semela

uphawu oluphambili

1. I-torque enkulu kwi-frequency ephantsi kunye nemveliso ezinzileyo

2. Ulawulo lwe-vector oluphezulu

3. Impendulo ye-torque eguqukayo ngokukhawuleza kunye nokuchaneka kozinzo olukhawulezayo

4. Cotha isantya kwaye uyeke ngokukhawuleza

5. Ikhono elinamandla lokuchasana nokuphazamiseka

Iinkqubo zokusebenza

1. Ukuhlolwa ngaphambi kokuba uqhube

1.1 Yongeza igrisi efanelekileyo ngokwetshathi yomatshini wokuthambisa.

1.2 Qwalasela zonke izixhobo zombane, umqheba, iinxalenye zothumelo, izixhobo zokukhusela kunye nokunciphisa izixhobo ziphelele, zithembekile kwaye ziguquguquka.

1.3 Isixhobo ngasinye kufuneka sibe kwindawo ye-zero, kwaye ukunyanzeliswa kwebhanti kufuneka kuhlangabezane neemfuno.

1.4 Akuvumelekanga ukugcina izinto zetsimbi ngokuthe ngqo ebhedini, ukuze ungonakalisi ibhedi.

1.5 Umsebenzi oza kucutshungulwa awunaludaka kunye nesanti, ukuthintela udaka kunye nesanti ukuba zingaweli kwi-pallet kwaye ziguge isiporo sesikhokelo.

1.6 Phambi kokuba i-workpiece icinezelwe, makuqhutywe uvavanyo lwemoto olungenanto.Emva kokuqinisekisa ukuba yonke into iyinto eqhelekileyo, i-workpiece inokulayishwa.

2. Iinkqubo zokusebenza

2.1 Emva kokuba i-workpiece ifakwe, qalisa impompo yeoli yokuthambisa kuqala ukuze wenze uxinzelelo lweoyile luhlangabezane neemfuno zesixhobo somatshini ngaphambi kokuba uqale.

2.2 Xa ulungelelanisa i-rack gear rack, xa ulungelelanisa ivili lokulenga, umbane kufuneka unqunyulwe.Emva kokulungelelaniswa, zonke iibholiti kufuneka ziqiniswe, i-wrench kufuneka isuswe ngexesha, kwaye i-workpiece kufuneka ikhutshwe ukuze isebenze ngokulinga.

2.3 Emva kokulayisha kunye nokukhulula i-workpiece, i-chuck wrench kunye neendawo ezidadayo ze-workpiece kufuneka zisuswe ngokukhawuleza.

2.4 I-tailstock, i-crank handle, njl. njl

2.5 Izixhobo zokusebenza, izixhobo zokusebenza kunye nezixhobo kufuneka zixhonywe ngokukhuselekileyo.Isixhobo samandla adadayo kufuneka sandise i-lead-in part kwi-workpiece ngaphambi kokuqala isixhobo somatshini.

2.6 Xa usebenzisa indawo yokuphumla yeziko okanye indawo yokuphumla, iziko elo malihlenga-hlengiswe kakuhle, yaye makubekho i-lubrication elungileyo neendawo zoqhagamshelwano ezixhasayo.

2.7 Xa ulungisa izinto ezinde, inxalenye ephumayo emva kwe-shaft engundoqo akufanele ibe yinde kakhulu.

2.8 Xa utyisa imela, imela kufuneka isondele emsebenzini kancinane ukuthintela ukungqubana;isantya senqwelo kufuneka sifane.Xa utshintsha isixhobo, isixhobo kunye nomsebenzi kufuneka sigcine umgama ofanelekileyo.

2.9 Isixhobo sokusika kufuneka siboshwe, kwaye ubude bokwandiswa kwesixhobo sokuguqula ngokuqhelekileyo abudluli amaxesha angama-2.5 ubukhulu besixhobo.

2.1.0 Xa kusetyenzwa iindawo eziziintsintsi, kufuneka kubekho ubunzima obuchanekileyo bokulinganisa umbindi womxhuzulane we-chuck, kwaye isantya sesithuthi masifaneleke.

2.1.1.Kufuneka kubekho imilinganiselo yokukhusela i-workpieces ehamba ngaphaya kwe-fuselage.

2.1.2 Uhlenga-hlengiso lwesethingi yesixhobo malucothe.Xa isicatshulwa sesixhobo si-40-60 mm kude nenxalenye yokucubungula ye-workpiece, i-manual okanye isondlo sokusebenza kufuneka sisetyenziswe endaweni yoko, kunye nokutya okukhawulezayo akuvumelekanga ukuba kubandakanyeke ngqo isixhobo.

2.1.3 Xa upholisha i-workpiece ngefayile, isibambi sesixhobo kufuneka sibuyiselwe kwindawo ekhuselekileyo, kwaye umqhubi kufuneka ajongane ne-chuck, ngesandla sasekunene ngaphambili kunye nesandla sasekhohlo ngasemva.Kukho isitshixo ebusweni, kwaye i-workpiece enembobo yesikwere ayivumelekanga ukuba iqhutywe ngefayile.

2.1.4 Xa upholisha isangqa sangaphandle se-workpiece ngelaphu le-emery, umqhubi kufuneka abambe iziphelo zombini zelaphu le-emery ngezandla zozibini ukuze azipolishe ngokwendlela yokuma echazwe kwinqaku elidlulileyo.Akuvumelekanga ukusebenzisa iminwe yakho ukubamba ilaphu le-abrasive ukupolisha umngxuma ongaphakathi.

2.1.5 Ngexesha lokutya okuzenzekelayo, umnini-mela omncinci kufuneka ulungelelaniswe ukuze uhlambuluke kunye nesiseko ukukhusela isiseko ekuthinteni i-chuck.

2.1.6 Xa usikwa ii-workpieces ezinkulu nezinzima okanye izixhobo, kufuneka kugcinwe isibonelelo esaneleyo somatshini.

3. Umsebenzi wokupaka

3.1 Sika umbane kwaye ususe i-workpiece.

3.2 Iziphatho zenxalenye nganye ziwiswa phantsi ukuya kwindawo enguziro, kwaye izixhobo zibalwe zize zicocwe.

3.3 Jonga imeko yesixhobo ngasinye sokukhusela.

4. Izilumkiso ngexesha lokusebenza

4.1 Akuvumelekanga ngokungqongqo ukuba abantu abangasebenziyo basebenzise umatshini.

4.2 Akuvumelekanga ngokungqongqo ukubamba isixhobo, inxalenye ejikelezayo yesixhobo somatshini okanye i-workpiece ejikelezayo ngexesha lokusebenza.

4.3 Akuvumelekanga ukusebenzisa isitophu sikaxakeka.Kwimeko yongxamiseko, emva kokusebenzisa eli qhosha ukuyeka, kufuneka lihlolwe kwakhona ngokwemigaqo ngaphambi kokuqala isixhobo somatshini.

4.4 Akuvumelekanga ukunyathela kumphezulu kaloliwe wesikhokelo, isikrufu intonga, intonga epolishiweyo, njl.njl.Ngaphandle kwemimiselo, akuvumelekanga ukusebenzisa isibambo ngeenyawo endaweni yezandla.

4.5 Kwiindawo ezinamabhula, imingxuma eyanciphayo okanye izitshixo eludongeni lwangaphakathi, i-triangular scrapers ayivumelekanga ukusika imingxuma yangaphakathi.

4.6 Umoya ocinezelweyo okanye uxinzelelo lolwelo lwe-pneumatic hydraulic chuck yangasemva kufuneka lufikelele kwixabiso elichaziweyo phambi kokuba lusetyenziswe.

4.7 Xa ujika ii-workpieces ezibhityileyo, xa ubude obuphumayo bamacala amabini angaphambili entloko yebhedi bungaphezu kobukhulu obuphindwe ka-4 ububanzi, iziko kufuneka lisetyenziswe ngokwemigaqo yenkqubo.Ukuphumla kweziko okanye inkxaso yokuphumla kwesithende.Abalindi kunye neempawu zokulumkisa kufuneka zongezwe xa ziphuma emva kwentloko yebhedi.

4.8 Xa usika isinyithi esiqhekezayo okanye ukusika ukutshiza ngokulula (kubandakanywa nokugaya), ii-baffles zokukhusela kufuneka zongezwe, kwaye abaqhubi kufuneka banxibe iiglasi zokukhusela.

Imiqathango yokusetyenziswa

Ukusetyenziswa okuqhelekileyo kweeleyile eziqhelekileyo kufuneka kuhlangabezane nale miqathango ilandelayo: ukuguquguquka kwamandla ombane kwindawo yesixhobo somatshini kuncinci, ubushushu be-ambient bungaphantsi kwama-30 degrees Celsius, kwaye ukufuma okuhambelanayo kungaphantsi kwama-80%.

1. Iimfuno zokusingqongileyo kwindawo yesixhobo somatshini

Indawo yesixhobo somatshini kufuneka ibe kude nomthombo wokungcangcazela, ukukhanya kwelanga ngokuthe ngqo kunye nemitha ye-thermal kufuneka kugwenywe, kwaye impembelelo yomswakama kunye nokuhamba komoya kufuneka kugwenywe.Ukuba kukho umthombo wokungcangcazela kufutshane nesixhobo somatshini, iigrooves ezichasene nokungcangcazela kufuneka zimiselwe malunga nesixhobo somatshini.Ngaphandle koko, kuya kuchaphazela ngokuthe ngqo ukuchaneka komatshini kunye nokuzinza kwesixhobo somatshini, okuya kubangela uqhagamshelwano olubi lwamacandelo e-elektroniki, ukungaphumeleli, kunye nokuchaphazela ukuthembeka kwesixhobo somatshini.

2. Iimfuno zamandla

Ngokuqhelekileyo, iileyile eziqhelekileyo zifakwe kwiworkshop yomatshini, kungekuphela nje ubushushu bemozulu eguqukayo kakhulu, iimeko zokusetyenziswa zimbi, kodwa kukho neentlobo ezininzi zezixhobo ze-electromechanical, ezikhokelela ekuguquguqukeni okukhulu kwigridi yamandla.Ngoko ke, indawo apho i-lathes eqhelekileyo ifakwe khona idinga ukulawulwa ngokungqongqo kwamandla ombane.Ukuguquguquka kwamandla ombane kufuneka kube phakathi koluhlu oluvumelekileyo kwaye uhlale uzinzile.Ngaphandle koko, ukusebenza okuqhelekileyo kwenkqubo ye-CNC kuya kuchaphazeleka.

3. Iimeko zobushushu

Ubushushu be-ambient lathes eziqhelekileyo bungaphantsi kwama-30 degrees Celsius, kwaye ubushushu obunxulumene bungaphantsi kwama-80%.Ngokuqhelekileyo, kukho i-fan exhaust okanye i-fan yokupholisa ngaphakathi kwebhokisi yokulawula yombane ye-CNC ukugcina ubushushu obusebenzayo bezinto ze-elektroniki, ngokukodwa iyunithi yokucubungula ephakathi, rhoqo okanye umahluko wobushushu utshintsha kancinci kakhulu.Ukushisa okugqithisileyo kunye nokufuma kuya kunciphisa ubomi bamacandelo enkqubo yokulawula kwaye kubangele ukusilela okwandisiweyo.Ukunyuka kweqondo lokushisa kunye nomswakama, kunye nokunyuka kothuli kuya kubangela ukudibanisa kwibhodi yesekethe edibeneyo kwaye kubangele isiphaluka esifutshane.

4. Sebenzisa isixhobo somatshini njengoko kuchaziwe kwincwadana

Xa usebenzisa isixhobo somatshini, umsebenzisi akavumelekanga ukuba atshintshe iiparitha ezibekwe ngumenzi kwinkqubo yokulawula ngokuthanda.Ukumiselwa kwezi parameters kuhambelana ngokuthe ngqo neempawu eziguquguqukayo zecandelo ngalinye lesixhobo somatshini.Kuphela ngamaxabiso eparamitha yembuyekezo yokubuyela umva anokulungiswa ngokweyona meko.

Umsebenzisi akakwazi ukutshintsha izixhobo zesixhobo somatshini ngokuthanda kwakhe, njengokusebenzisa i-hydraulic chuck ngaphaya kokucaciswa.Umenzi uqwalasela ngokupheleleyo ukuhambelana kweeparitha ezahlukeneyo zekhonkco xa ubeka izixhobo.Ukutshintshwa kweemfama kubangela ukungahambelani kweeparamitha kumakhonkco ahlukeneyo, kwaye kubangele neengozi ezingalindelekanga.Uxinzelelo lwe-chuck ye-hydraulic, i-hydraulic tool rest, i-hydraulic tailstock kunye ne-cylinder ye-hydraulic kufuneka ibe ngaphakathi koluhlu loxinzelelo oluvumelekileyo, kwaye aluvumelekanga ukuba lwande ngokungqongqo.

Ixesha lokuposa: Sep-09-2022