Iimpawu zezixhobo zoomatshini be-CNC ekusebenzeni

1. Ukuchaneka okuphezulu

(1) Isakhiwo sesixhobo somatshini wezixhobo zomshini we-CNC sinokuqina okuphezulu kunye nokuzinza kwe-thermal, kwaye amanyathelo okunciphisa iimpazamo athathiweyo.Ngempazamo, inokuthi ibuyekezwe ngesixhobo sokulawula amanani, ngoko ke isixhobo somatshini wokulawula amanani sinokuchaneka okuphezulu komatshini.

(2) Inkqubo yokuhanjiswa kwesixhobo somatshini we-CNC ithatha i-screw yebhola ngaphandle kwemvume, i-rolling guide rail, i-gear mechanism ene-zero clearance, njl., ephucula kakhulu ukuqina kokuhanjiswa, ukuchaneka kokuhanjiswa kunye nokuphindaphinda kwesixhobo somatshini.Isixhobo somatshini esiphucukileyo se-CNC samkela itekhnoloji yemoto yelinear, ukwenzela ukuba impazamo yokuhanjiswa koomatshini besixhobo somatshini ibe zero.

(3) Umsebenzi wembuyekezo yempazamo yenkqubo yolawulo lwamanani ususa impazamo yenkqubo.

(4) Isixhobo somatshini we-CNC sisebenza ngokuzenzekelayo, sisusa impazamo yomntu, siphucula ukuhambelana kobungakanani bokusebenza kweqela elifanayo leenxalenye, kwaye umgangatho wokucubungula uzinzile.Ufakelo olunye lunokuqhuba inkqubo eqhubekayo yeenkqubo ezininzi, ukunciphisa iimpazamo zokufakela.

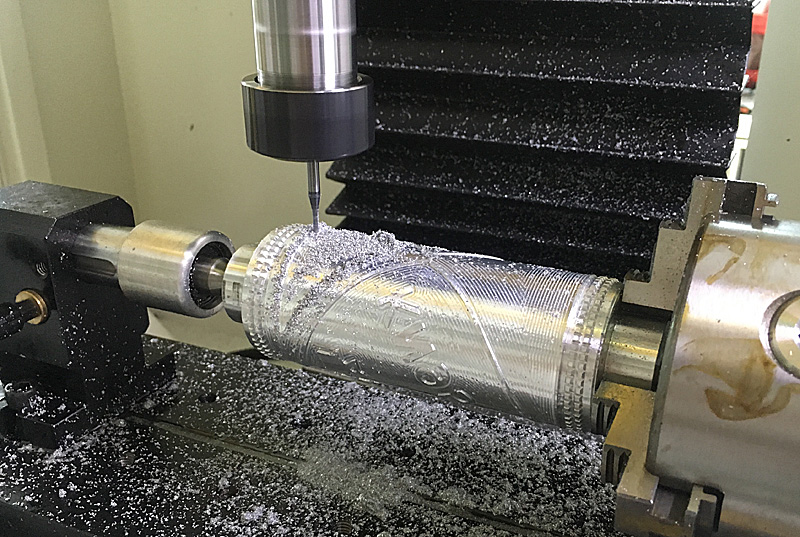

2. Uyakwazi ukucubungula iindawo ezinemilo enzima

Isebenzisa isixhobo somatshini we-CNC oneezembe ezingaphezulu ezimbini ezidityaniswe kunye, inokuqhubekekisa umzimba ojikelezayo, ikhamera, kunye neendawo ezahlukeneyo ezintsonkothileyo ezigobileyo ezinebhasi egobileyo, kwaye inokugqiba ukusetyenzwa okunzima kwizixhobo zoomatshini eziqhelekileyo.Umzekelo, ipropeller yaselwandle yinxalenye entsonkothileyo enomzimba ogobileyo wesithuba, onokuthi uqwalaselwe kuphela sisisikhi sokusila esinesiphelo kunye nesixhobo sokunxibelelana se-CNC esine-axis emihlanu.

3. Imveliso ephezulu

(1) Yonga ixesha elongezelelekileyo

Izixhobo zoomatshini be-CNC zixhotyiswe ngezixhobo ezizenzekelayo zokutshintsha izixhobo ezifana nokuphumla kwesixhobo sesalathisi kunye neemagazini zesixhobo.I-manipulator inokulayisha ngokuzenzekelayo kwaye ikhuphe izixhobo kunye nezixhobo zokusebenza, ezigcina kakhulu ixesha elincedisayo.Akukho ukuhlolwa okufunekayo kwinkqubo yokuvelisa, ukugcina ixesha lokuhlola.Xa inxalenye yomatshini itshintshiwe, ngaphezu kokuphinda ubambe i-workpiece kunye nokutshintsha isixhobo, inkqubo kuphela kufuneka itshintshwe, egcina ukulungiswa kunye nexesha lohlengahlengiso.Xa kuthelekiswa nezixhobo zoomatshini eziqhelekileyo, ukuveliswa kwezixhobo zoomatshini be-CNC kunokunyuswa ngamaxesha angama-2 ukuya kuma-3, kwaye imveliso yamaziko omatshini inokunyuswa ngeshumi ukuya kumaxesha amaninzi.

(2) Ukunyusa izinga lokutya

Izixhobo zoomatshini be-CNC zinokugcina ngokufanelekileyo ixesha lokulawula, ukunyakaza okukhawulezayo kunciphisa ixesha lokuhamba ngokungasebenziyo, kwaye uluhlu lokutya lukhulu.Unokukhetha ngokufanelekileyo inani elifanelekileyo lokusika.

(3) Ukusika ngesantya esiphezulu

Ngexesha lomatshini we-CNC, izixhobo ezinobubanzi obuncinci, ubunzulu obuncinci bokusika, ububanzi obuncinci bokusika, kunye nokupasa okuphindaphindiweyo kusetyenziselwa ukuphucula ukusebenza kakuhle kokusika.

Amandla okusika omatshini wesantya esiphezulu ancitshiswe kakhulu, kwaye i-torque efunekayo yokuphotha iyancitshiswa ngokuhambelanayo.

I-deformation ye-workpiece incinci.Ukusika kwesantya esiphezulu akugcini nje ukuphucula imveliso, kodwa kunceda ekuphuculeni ukuchaneka komatshini kunye nokunciphisa ubunzima bomhlaba.

Ukulungelelaniswa kunye neempawu zezoqoqosho zezixhobo zomatshini we-CNC

1. Ukuziqhelanisa okunamandla

Izixhobo zoomatshini be-CNC ziyakwazi ukuziqhelanisa nokusetyenzwa kwee-workpieces zeentlobo ezahlukeneyo, iinkcukacha kunye nobukhulu.Xa utshintsha iinxalenye ukuba zenziwe ngoomatshini, kuyimfuneko kuphela ukunyanzelisa i-workpiece nge-fixture yendalo yonke, ukutshintsha isixhobo, kunye nokutshintsha inkqubo ye-machining, kwaye umatshini unokwenziwa ngokukhawuleza.Inkqubo yolawulo lwamanani ekhompyuter inokusebenzisa isoftware yolawulo lwenkqubo ukunyusa ngokuguquguqukayo okanye ukuguqula imisebenzi yenkqubo yolawulo lwamanani, kwaye inokuhlangabezana neemfuno zophuhliso lwemveliso.

2. Uququzelela uphuhliso lweenkqubo zokuvelisa ezikumgangatho ophezulu

Izixhobo zoomatshini be-CNC zizixhobo ezisisiseko zomatshini wokuzenzekelayo.Iiseli ze-Flexible machining (FMC), iinkqubo zokuvelisa eziguquguqukayo (FMS) kunye neenkqubo zokuvelisa ezidibeneyo zekhompyutheni (i-CIMS) zonke zisekelwe kwizixhobo zomatshini we-CNC.Isixhobo esinye okanye ezingaphezulu zoomatshini be-CNC, kunye nezinye izixhobo ezincedisayo (ezifana neetroli zothutho, iirobhothi, iibhentshi zokusebenzela ezitshintshayo, iindawo zokugcina iimpahla ezinamacala amathathu, njl. njl.) zenza inkqubo yokuvelisa ezenzekelayo.Inkqubo yolawulo lwamanani inonxibelelwano lonxibelelwano, olulula ukunxibelelana phakathi kweekhompyuter kunye nokuqonda ulawulo lwekhompyuter kunye nolawulo lwenkqubo yokuvelisa.

3. Uqoqosho lwezixhobo zoomatshini be-CNC

Iindleko zezixhobo zoomatshini be-CNC ziphezulu kunezo zixhobo zoomatshini eziqhelekileyo, kwaye iindleko zokucubungula ziphezulu.Ke ngoko, ayizizo zonke iindawo ezilungele ukusetyenzwa kwizixhobo zoomatshini be-CNC, kwaye inoluhlu oluthile lwezicelo zokusetyenzwa.Ingaba ifanelekile kwi-CNC isixhobo sokulungiswa kwesixhobo kufuneka sinqunywe ngokohlobo lwemveliso, ubungakanani besakhiwo kunye nobunzima bemveliso.

Isixhobo somatshini esiqhelekileyo sifanelekile kwimveliso enye kunye nencinci encinci, kwaye isakhiwo sokucubungula asinzima kakhulu.

Izixhobo zomatshini ezikhethekileyo zifanelekile ukuqhutyelwa kwezinto ezininzi zokusebenza.

Izixhobo zoomatshini be-CNC zifanelekile kwi-batch processing ye-workpieces ezinzima.

Iimpawu zezixhobo zoomatshini be-CNC kulawulo kunye nokusetyenziswa

Izixhobo zoomatshini be-CNC ziyabiza ukwenza, kwaye zizixhobo eziphambili kwiimveliso eziphambili kunye neenkqubo eziphambili kwishishini.Emva kokuba umatshini ungaphumeleli, impembelelo kunye nelahleko iya kuba nkulu.Njengesixhobo se-mechatronics, izixhobo zoomatshini be-CNC zineempawu zazo.

Inqanaba lobugcisa bolawulo, ukusebenza, ukugcinwa kunye nabasebenzi beprogram kuphezulu kakhulu.Isiphumo sokusetyenziswa kwezixhobo zoomatshini be-CNC kuxhomekeke kumlinganiselo omkhulu kumgangatho wobugcisa bomsebenzisi, ukuqulunqwa kobugcisa bomatshini be-CNC kunye nokuchaneka kweprogram ye-CNC.Ke ngoko, itekhnoloji yokusetyenziswa kwezixhobo zomatshini we-CNC ayiyongxaki yokusetyenziswa kwezixhobo ngokubanzi, kodwa iprojekthi yesicelo sobugcisa beetalente, ulawulo kunye neenkqubo zezixhobo.Abasebenzisi bezixhobo zoomatshini be-CNC kufuneka babe nolwazi lwenkqubo ecebileyo, kwaye ngelo xesha babe namandla okusebenza aqinileyo ekusebenziseni iteknoloji ye-CNC, ukwenzela ukuba kuqinisekiswe ukuba izixhobo zomatshini ze-CNC zinezinga eliphezulu lokuthembeka kunye nezinga lokusebenza.

Iindidi zenkqubo ye-CNC

Udweliso lwenkqubo lweNC lwahlulwe lwaba ngamacandelo amabini: inkqubo yezandla kunye nenkqubo ezenzekelayo.

1. Ukwenza inkqubo ngesandla

(1) Ukumisela inkqubo yeteknoloji Ngokwecandelo lomzobo, uhlalutyo lwenkqubo luyenziwa, kwaye iiparitha zeteknoloji ezifana nomzila wezobuchwepheshe, ulandelelwano lwamanyathelo okusebenza, inani lokusika kunye nokunye kokucutshungulwa kwenxalenye kunqunywe.Qinisekisa izixhobo kunye nenani lezixhobo zokusebenzisa.

( 2 ) Bala umkhondo womatshini kunye nobukhulu

(3) Bhala uluhlu lwenkqubo kwaye uluqinisekise

(4) Faka umxholo woluhlu lwenkqubo Umxholo woluhlu lwenkqubo yolawulo lwamanani igalelo kwisixhobo sokulawula amanani ngesixhobo sokufaka.

(5) Ukuqinisekiswa kunye nokusikwa kwesilingo seprogram ye-NC Qala isixhobo se-NC, yenza isixhobo somshini we-NC siqhube some, kwaye ukhangele ukuchaneka kweprogram yeprogram.Sebenzisa iplanga okanye iimveliso zeplastiki endaweni yomsebenzi wokusika isilingo ukujonga ukuchaneka kwexabiso lokusika.

(6) Isilingo sokusika isiqwenga sokuqala

2. Ucwangciso oluzenzekelayo

Inkqubo yokuqulunqa iinkqubo zomatshini ze-CNC ngoncedo lwekhompyutha ibizwa ngokuba yinkqubo ezenzekelayo.

Kwiindawo ezinejometri ezintsonkothileyo, inkqubo yezandla inzima kakhulu kwaye ineempazamo.

Ukucwangcisa kunye nokubalwa kweendawo zomphezulu wesithuba kunzima kakhulu, kwaye umsebenzi wezandla awunakukwazi.Kwiprogram ezenzekelayo, ukubalwa kwedatha ye-node coordinates, ukuveliswa kweendlela zesixhobo, ukucwangciswa kwenkqubo kunye nemveliso yeenkqubo zonke zenziwa ngokuzenzekelayo yikhompyutha.

Ixesha lokuposa: May-23-2022